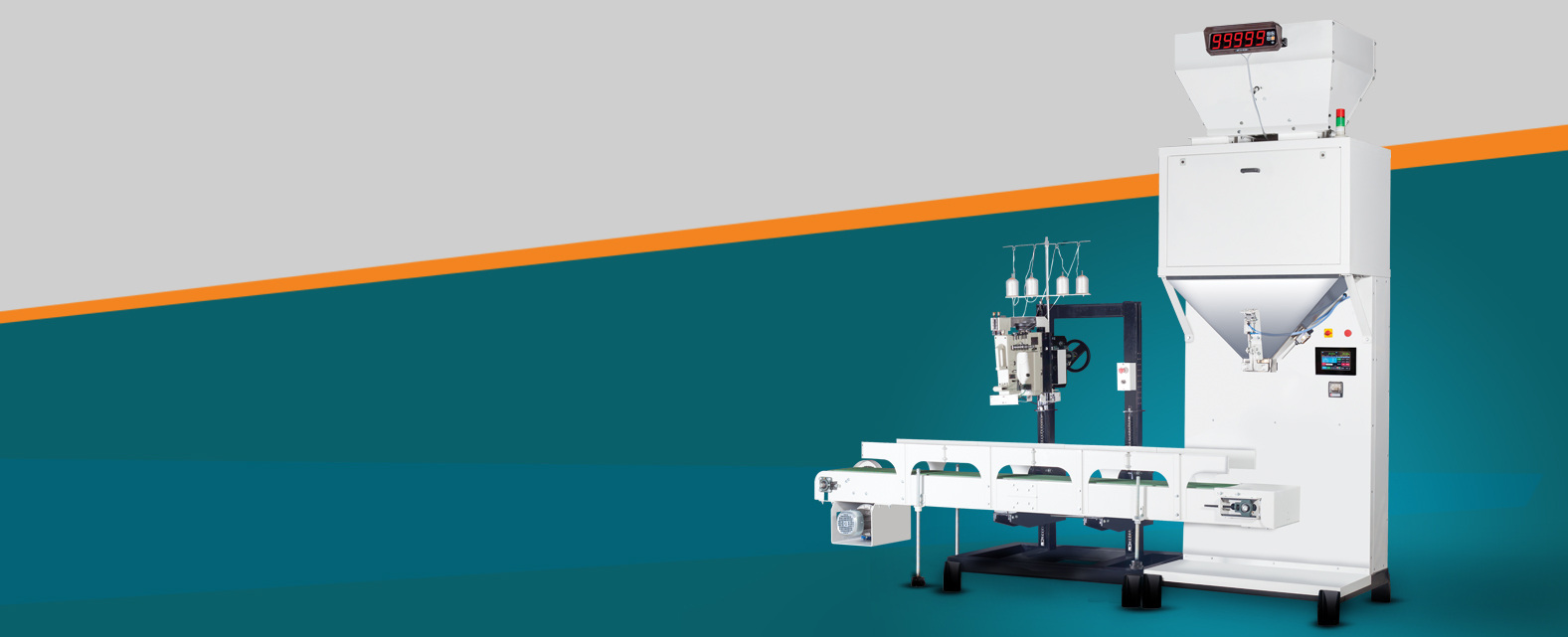

Features

| -Weighing, filling and packing within 5 seconds. |

| -Weighing, filling and Conveying by one- touch. |

| -Suitable for different weigh bag lot production. |

| -Machine space is minimized with integerated control panel. |

| -Printer output document for account management. |

| -Large external display for easy supervision. |

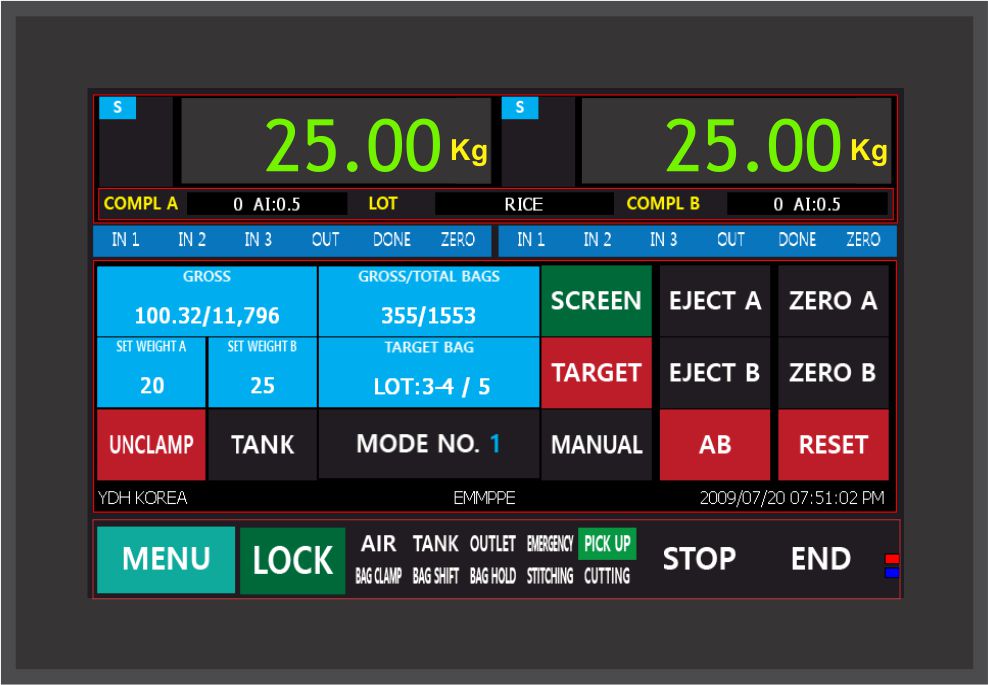

User Friendly Color Touch HMI

Purpose

Weighing

Recording

Packing

![]()

Stitching

![]()

Facilities

| Easy change mode setting | Accept/Reject indication |

| Operator can change different weigh bags without getting into precise setting. | Accept and reject bags based on tolerance of weight. |

| Remote View | Bag height adjustment |

| Manager can have a view of packing process at his desk. | Simple gear hand wheel to adjust conveyor height for various bags. |

| Target and Bag Count | Fault Diagnosis |

| Easy to fix target bag and count no. of bags. | Builtin self diagnosis function to prevent trouble and down time. |

| Simultaneous falling | Bag closure option |

| Both weighing can fill simultaneously to get odd packing weights. | Plain closure / Fold over closure / Crepe Tape closure / PP Tape closure. |

Specification

| Model | Bag Size | ||

| MWB 25D | Width-195mm-500mm, Height-400mm-700mm | ||

| Weighing Materials | Control method | ||

| Free Flow Grain | Built in Micom | ||

| Weighing Method | Power Source | ||

| Load cell type 3step gates (1unit) | 3Phase, AC 415V, 2KW | ||

| Weighing Range | Air Utility | ||

| 5kg - 25kg (50kg - Optional) | 400NL/Minute, 6kgf/sq.cm (Compressor-2.5kw or above) | ||

| Weighing Accuracy | Machine Dimension | ||

| 0.1% FSD | 930(W)x1200(D)x1850(H) | ||

| Packing Capacity | Machine Weight | ||

| 10 - 14bag / min | Approx 350kg | ||

| Packing Material | Stitching Machine | ||

| Jute, PP, Non woven and paper | Single/Double Stich (optional) |

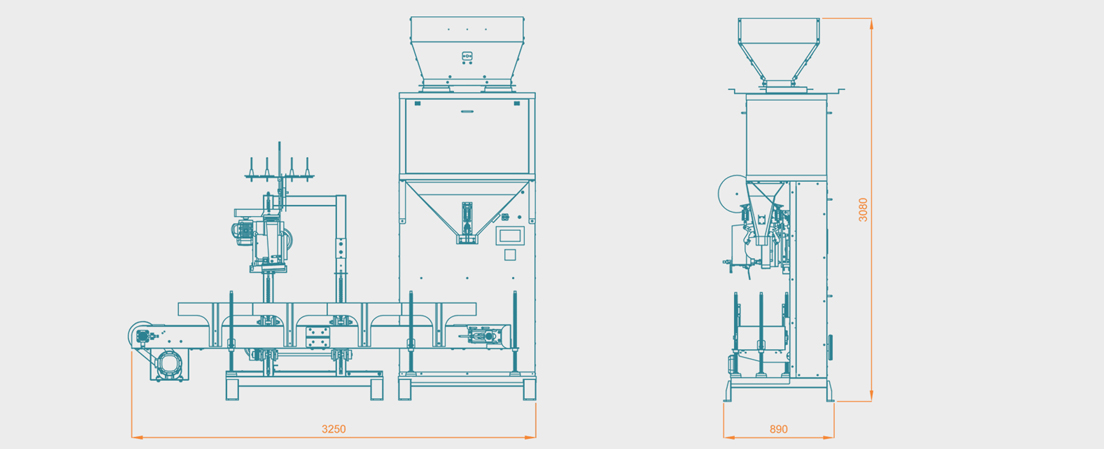

Diagram